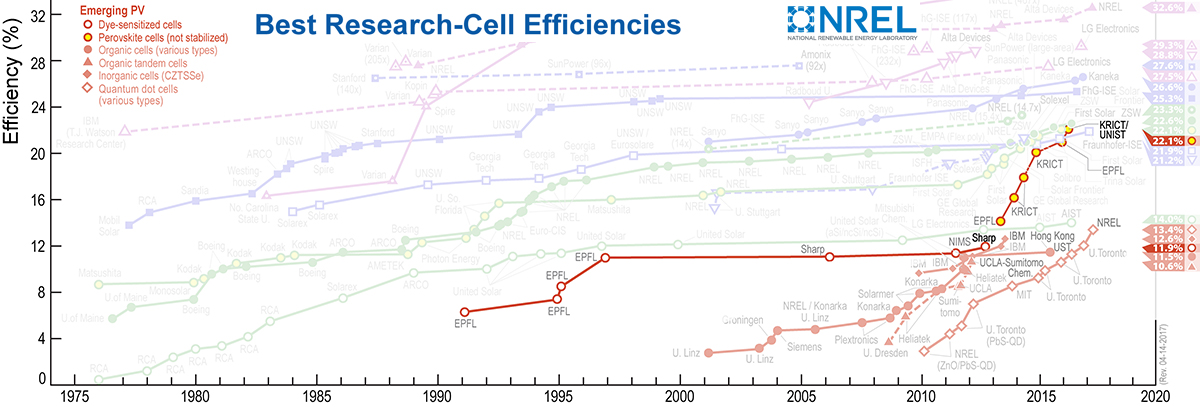

Emerging photo-voltaic technologies have developed rapidly and, in the case of perovskite based materials, are approaching the efficiencies of Crystalline Silicon based solar cells. Dye Sensitized Solar Cells (DSSC) have attracted interest due to their flexibility, transparency, and low materials cost.

Image copyright National Renewable Energy Laboratory

Image copyright National Renewable Energy Laboratory

Many of our customers are pursuing research in these areas and are using their Laurell spin coaters to produce ever more efficient solar cell designs. Our equipment has been refined through 32 years of experience and provides significant advantages.

Safe Chemistry Handling

Common chemicals used in perovskite PV research, such as: DSMO, DMF, and Chlorobenzene are toxic, and when used in combination, can adversely effect your equipment.

Laurell spin coaters separate the process chamber, and the chemistry used, from the motor and control electronics. Gas purge, through a triple labyrinth seal, ensures this isolation, and extends the operational life of your spin coater.

Processing in an inert atmosphere is possible when the correct pressure differential is observed.

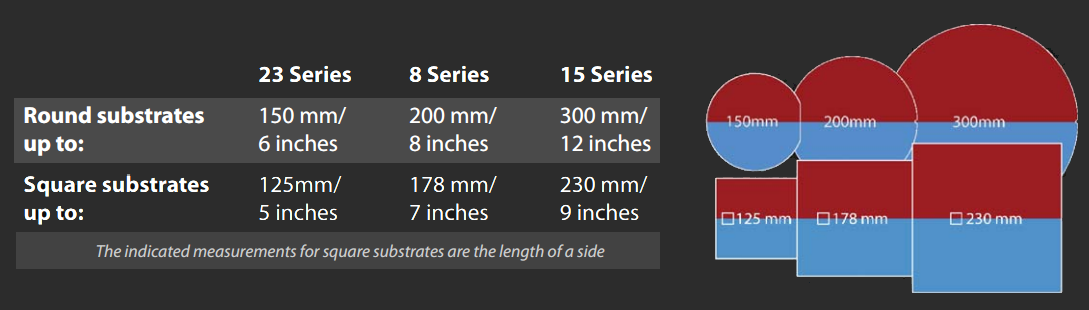

Flexible Sizing

Unlike many box-like systems, you are not limited by the size of our housing should you need to process larger scale substrates. Our 23 series spin coaters allows splash-back-free processing of substrates up to 150mm in diameter, or square substrates of up to 125mm on a side.

High Performance Motor

Your best option for perovskite processing is a Laurell Hz Series spin coater that includes our brushless High Performance motor.

Backed by a limited lifetime warranty, this motor allows high speed, high acceleration, and rotation in either direction — agitation routines available within each process step.

Substrate Handling

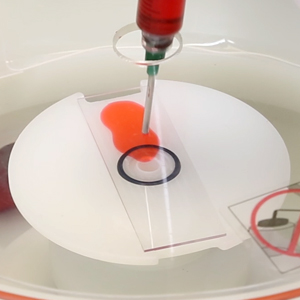

Many of the substrates used for DSSCs are flexible and benefit from a high porosity chuck, where the entire surface area of the substrate is supported and held under vacuum.

Using the right chuck improves coating quality. High porosity chucks for standard cover slip sizes and embedded chucks for standard microscope slides are available direct from Laurell.

If you have an unusual shape and/or size substrate, a custom chuck can be made for a perfect fit.