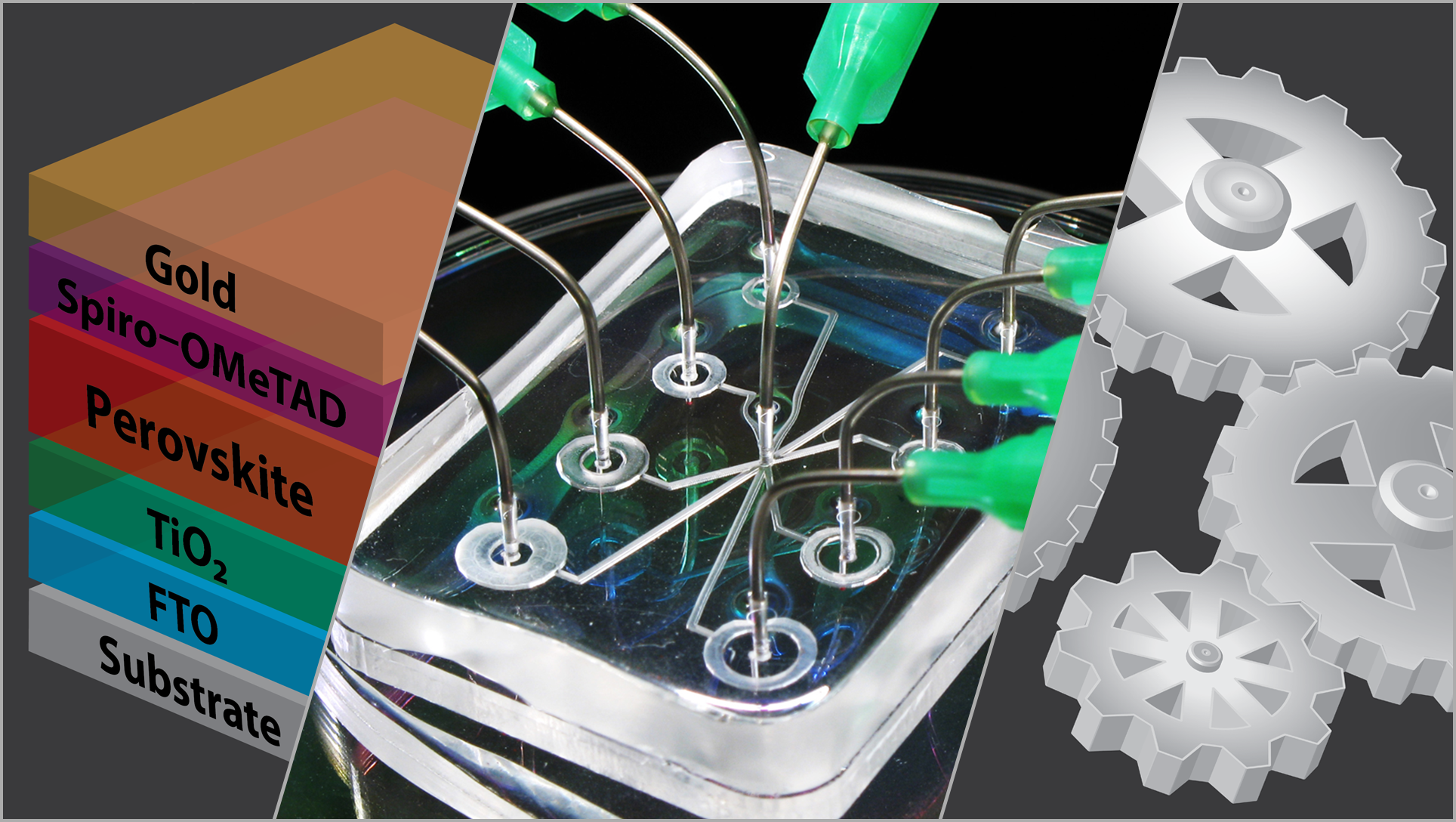

New User Interface and Process Controller

We have brought together custom hardware and software to design an entirely new, intuitive touch screen controller.

- Easy program creation and editing

- Administrator and user accounts with security

- Documentation and certification available directly on the system

- Reliable Bluetooth connection for day-to-day use

- Wired connection available from the factory for non-wireless environments

- Fully protected custom hardware that is reliable and robust

Brushless Motor

Our high-performance, brushless motor allows greater flexibility in your process development.

- Spin speeds from 1 to 12,000 RPM and acceleration up to 12k RPM/Second*

- Bi-directional rotation at a full speed range; programmable agitation

- An optional end-of-process homing feature returns chuck and substrate to the same position every time

- Suitable for use in inert gas atmospheres or pressurized gloveboxes

- The 750 spin coater features a 3-year warranty

- The 750 motor is backed by a 7-year limited lifetime warranty

Backwards compatible with 650 series accessories, and chucks.

*Spin speeds and acceleration are dependent on size and weight of chuck and substrateThe Laurell Advantage

- Seamless co-polymer housing resistant to solvents and acids at concentrations < 50% and temperatures < 50°C

- Our ClearView impact and chemically resistant lid

- Large process chamber and fluid control design contains and directs waste material away from the substrate and into the drain

- New "Lid-Loc" system allows for quick exchange of lid-mounted accessories

- Each step of your program can be set from 1 second to 99 minutes 59.9 seconds in 0.1 second increments

Certified Safe

Laurell Technologies' new 750 series systems have been tested for mechanical safety and electromagnetic compatibility by Intertek, a Nationally Recognized Testing Laboratory.

Laurell Technologies is authorized to use the ETL mark on approved systems.

Laurell systems have passed:

- A 5 Joule impact test

- A block rotor test. Our motors were mechanically prevented from turning and did not suffer any damage or exceed heat limits

- Continuous duty testing over extended periods

All Laurell products that carry the ETL mark meet, or exceed, specific US and Canadian product safety standards. These standards conform to those required for CE and UKCA marking.

Options and Accessories

Tailor your system to fit your process and your budget.

Syringe holders to make manual dispense easier.

Programmable automated dispense with 0.1 second timing, accurate dispense volumes, and easy adjustment allows for the most consistent and reliable coatings.

The new Laurell 750 spin coater, designed for all your processes.